Physical & Analytical Testing:

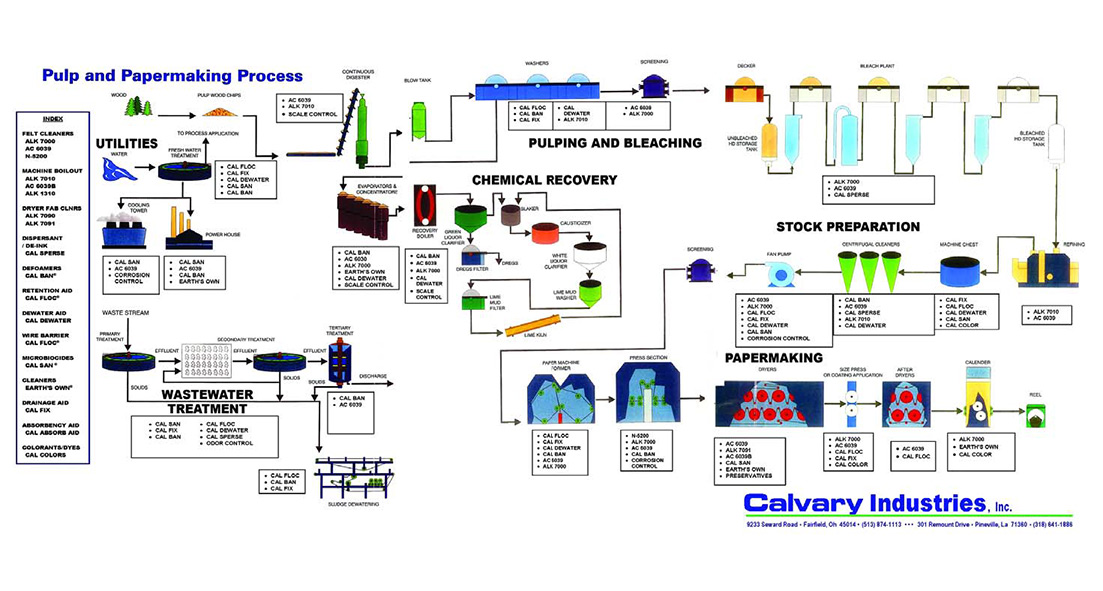

Pulp / Papermaking Process Diagram:

Time is money and every operational minute is critical to the bottom line. Keeping the processes cleaner will result in reduced maintenance and less downtime for felt and dryer fabric change-outs. Calvary’s analytical capabilities will help illustrate how we can improve overall cleanliness without reducing quality, subsequently keeping your felts and dryer fabrics in service for a longer period of time.

Our Test Lab utilizes both a TAPPI Disintegrator and a Britt Jar to evaluate polymer effectiveness, drainage rates, repulping efficiency and stickies control. A handsheet mold is used to manufacture handsheets under controlled conditions for visual and microscopic examination to determine the effect of comparative chemistries.

Our lab has a series of dynamic foam cells for testing the efficacy of defoamers in paper stock systems.

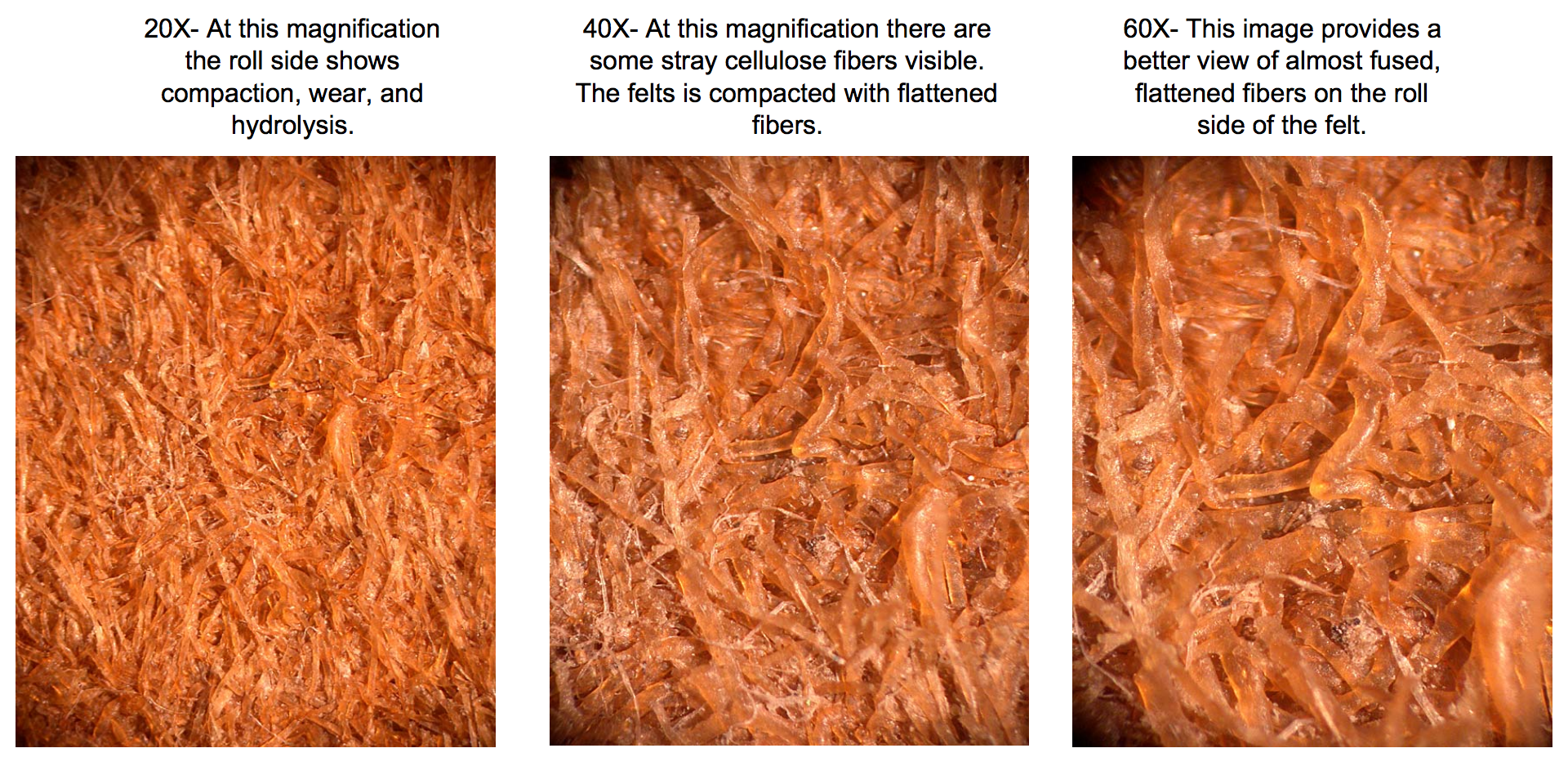

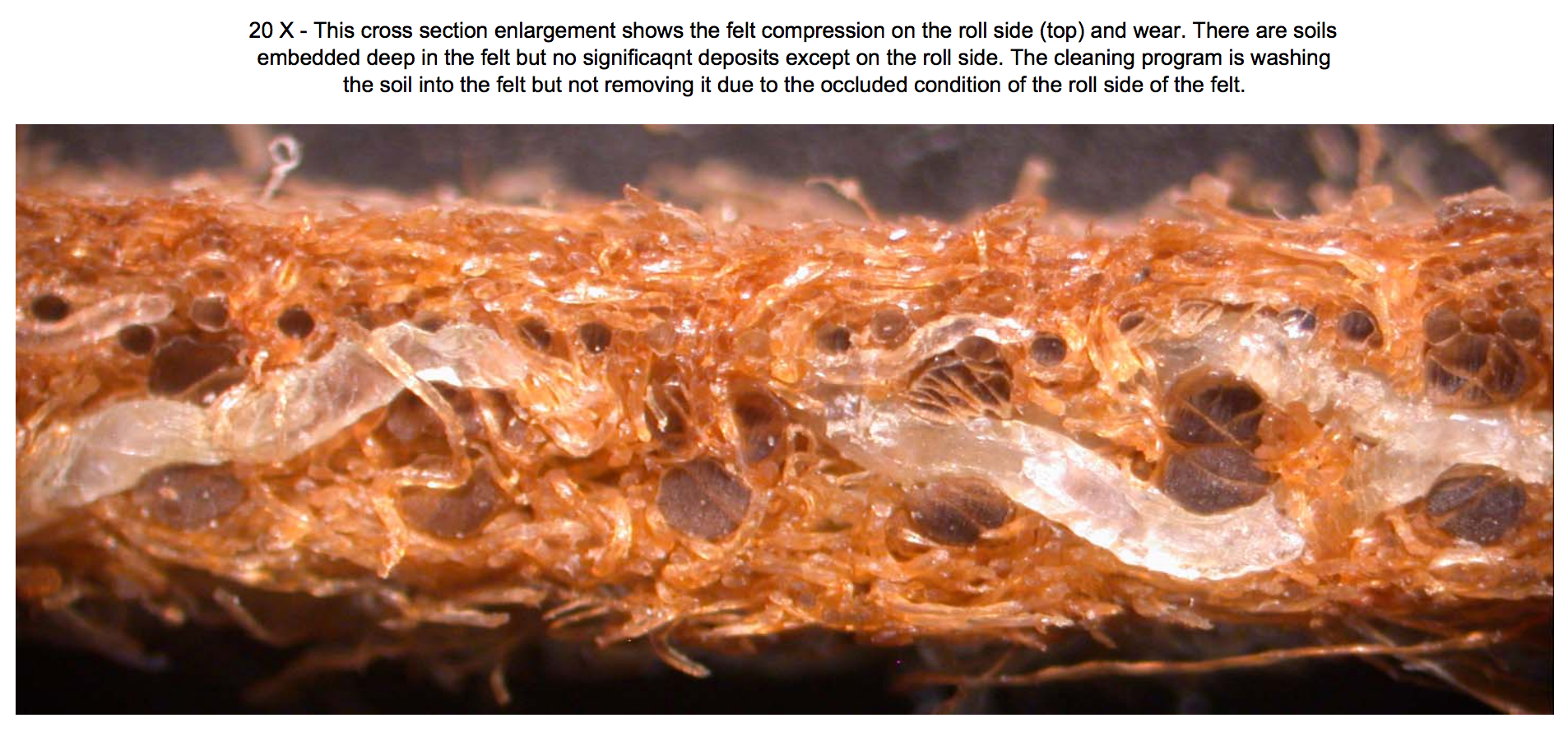

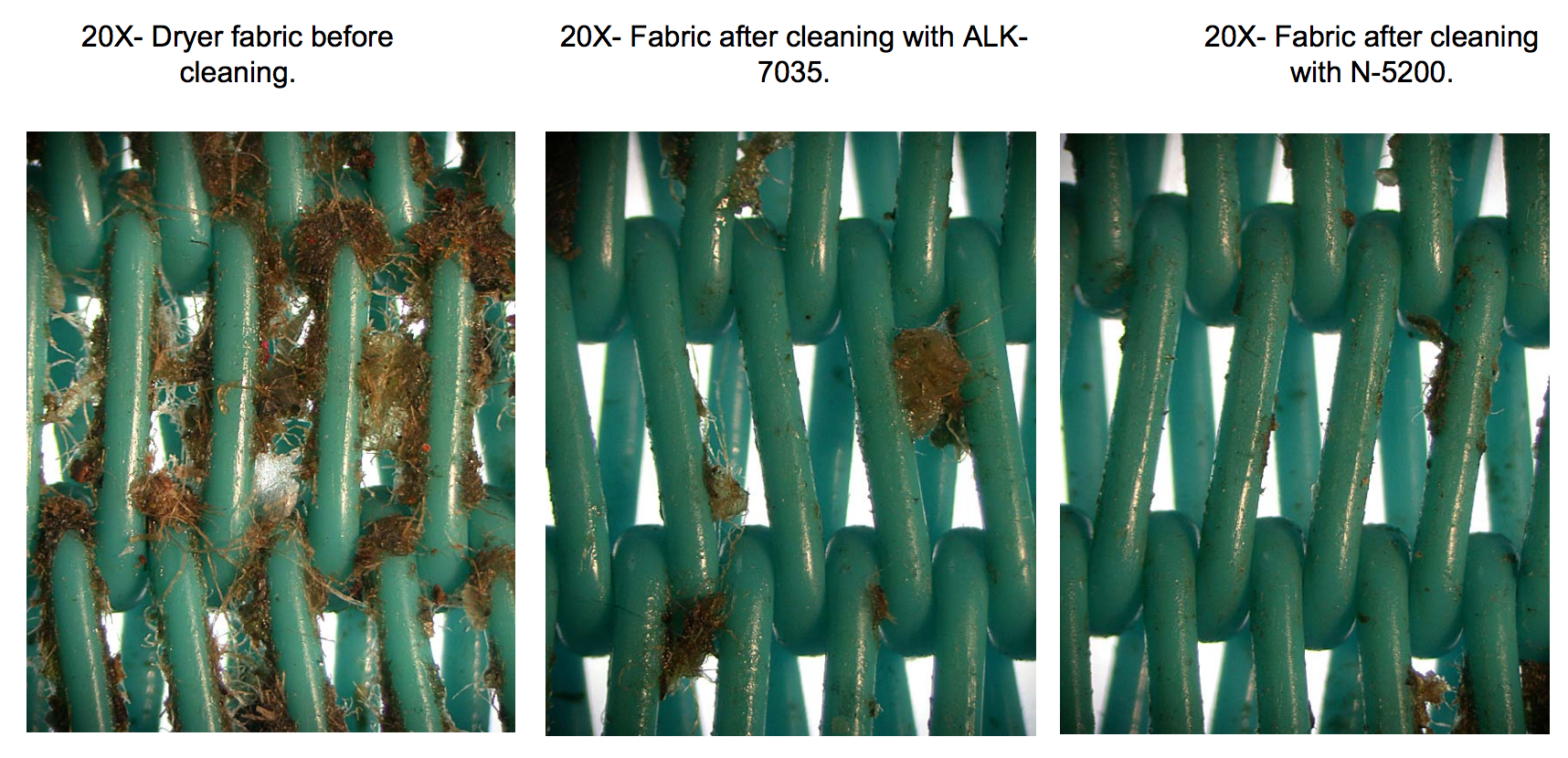

To support the felt cleaning applications, a Lorentzen and Wettre Felt Permeability Tester is available on-site to determine the condition of the felt and the improvement after the cleaning cycle. Calvary also has the capability to analyze used felts to determine their condition and the characteristic soils that are remaining in the felt. The analysis utilizes multiple solvent extraction techniques, ash determination, alkali extraction and microscopic examination to determine the condition of the felt, therefore allowing us to provide solutions to the evident issues. Cleaning studies are also conducted to determine the most effective products and cleaning methods to remove the problematic soils in the felt. A report showing the loading of soils, microphotographs of the felt and recommendations for cleaning solutions is presented to the customer.

Analysis:

We'd love to hear from you.

CONTACT NOW ›